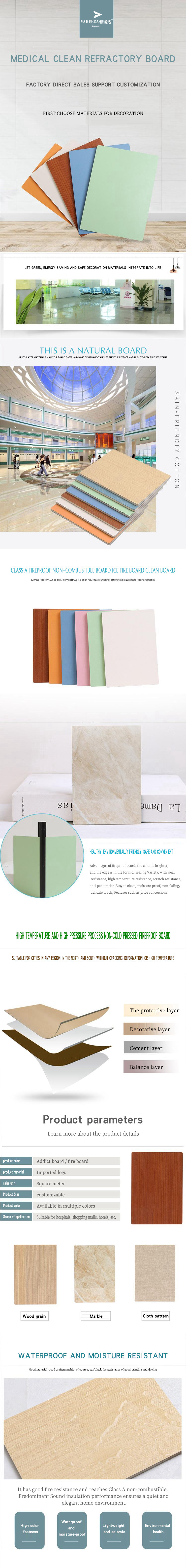

Medical clean refractory board

1、 Performance characteristics of arida ice fire cleaning board:

(1) Air hardness: common cementing materials are represented by general cement, which are all hydraulic, that is, they can harden in water. But the ice fire board is completely different from the conventional cement. It is air hard and does not harden in water. This is a prominent feature of magnesium cement compared with conventional cement.

(2) Multicomponent: ice fire board is multicomponent, light burned magnesium powder will not harden with water. One of its components is light burned magnesium powder or dolomite lime powder, the other is magnesium salt, the other contains water and modifier.

(3) High exothermic: ice fire plate in the hardening to release a high amount of heat. Its heat release capacity is 1 ~ 13.5kj/g, and the central temperature of the high response system can reach 140 ℃, which may exceed 150 ℃ in summer. The hydration heat of general cement is only 300 ~ 400j / g, and that of magnesium cement is 3 ~ 4 times of that of general cement.

(4) High strength: ice fire plate can easily reach 62.5mpa. Generally, the compressive strength of light burned magnesium powder can reach above 62.5mpa, and most of them can reach above 90Mpa. Under the condition that the quality of light burned magnesium powder can be ensured, the proportion of magnesium cement is reasonable, and the process is scientific, it can reach about 140MPa. The experimental results show that when the mass ratio of light burned magnesia powder to inorganic aggregate is 1:1, the 1D compressive strength can reach 34 MPa and the flexural strength can reach 9 MPa. The 28d compressive strength is 142mpa and the flexural strength is 26mpa.

(5) High temperature and low temperature resistance: in all kinds of inorganic cementitious materials, as long as the ice fire board has the characteristics of both high temperature and low temperature resistance. The fire resistance of MgO, the main component of light burned powder, is 2800 ℃. Therefore, the ice fire decorative panel generally has the characteristics of high temperature resistance, even if it is compounded with glass fiber, it can also withstand fire above 300 ℃. It is because of the fire resistance of magnesium cement that it is widely used to produce fireproof board.

(6) Light weight and low density: the density of ice fire board is only 70% of that of ordinary silicate products. The density of its products is generally 1600 ~ 1800kg / m3, while the density of cement products is generally 2400 ~ 2500kg / m3. So it has a very significant low density.

2、 Advantages and uses of arida ice fire clean board

The ice fire cleaning board is composed of a base material board, an adhesive layer and an adhesive impregnated paper. The base material board is an asbestos free fiber cement board, and the adhesive impregnated paper is a decoration paper impregnated with resin adhesive. It is a board made like ice fire, and the material is wood. Ice fire board has the characteristics of waterproof and fireproof, and can achieve the decoration function of real marble.

The utility model relates to an ice fire clean board, which belongs to the technical field of construction and decoration data. It looks like stone. In fact, the most common things we see, including the ice and fire on TV, are all about stone. In fact, the ice and fire board is similar to stone. The surface it produces is very similar to stone, and the grain and even sometimes marble.

Advantages of ice fire clean board:

Its advantage lies in its cost performance, low price, this is the most important, other installation is simple, and marble stone installation and transportation is very troublesome, and the ice fire plate is really very simple.

Ice fire clean board is also called fiber cement board. It is a new type of construction data, which is mainly made of siliceous and calcareous materials and maintained by various methods. Appear in the market with a new look, in the interior decoration, the exterior has a different style, with characteristic color.

Fire insulation: non combustible class A, the board will not be burned in case of fire, and will not produce toxic smoke; With low conductivity, it is an ideal insulation material, waterproof and moisture-proof, heat insulation and sound insulation, light weight and high strength, simple construction, economic and beautiful, safe and harmless, and long life.

Ice fire board uses special conductive pigment added in the coating of color board to make the surface of color board have 10-100 resistance, through which static electricity can be released to form electric energy, avoid dust adhesion, and simple removal. At the same time, the board has the advantages of drug resistance, wear resistance, pollution resistance, etc. Special enamel antibacterial agent is used in the coating of ice fire board, which has non-toxic and semi permanent anti bacteria effect and far infrared radiation effect.

Main uses:

Ice fire board is a kind of high performance and environment-friendly fire-proof self-cleaning inorganic precoated board developed for inorganic materials. It can be used as internal and external wallboard, interior partition, wall protection, ceiling, sign decoration board, etc.

Now it has been widely used in: electronic workshop clean room, food factory, pharmaceutical factory, daily chemical factory clean room, hospital sterile room, dust-free room, operating room, ward, subway station, underpass engineering, underground engineering, catering shop, other public wall, etc.

Promotion support

Contact Us

EMALL: yareeda0512@163.com Website: www.yreeda.com

Yaruida (Suzhou) Material Technology Co., Ltd. (Headquarters)

Address: 101 Huaxing Road, Wangting International Logistics Park, Xiangcheng District, Suzhou City, Jiangsu Province

Marketing Center: No. 403, Building 3, Xinhui City Jingyuan, South Side of Dawan Metro Station, Huxiang Street, High-speed Rail New City, Xiangcheng District, Suzhou City, Jiangsu ProvinceTel:0512-69575228

Tel: Mr. Wang 18306136363

Yaruida (Hefei) Decorative Building Materials Co., Ltd. (Branch)

Address: In the courtyard of Sibao Cable Factory, Wenzhong Road, Yaohai District, Hefei City, Anhui Province

Tel: Mr. Zhang 15156980083

Astec (Shijiazhuang) Decorative Building Materials Co., Ltd. (Branch)

Address: No. 4-114, No. 289, Heping East Road, Chang'an District, Shijiazhuang City, Hebei Province

Tel: 0311-85521592 Mr. Wang 13903312353

Yaruida (Suzhou) Material Technology Co., Ltd. (Headquarters)

Address: 101 Huaxing Road, Wangting International Logistics Park,

Marketing Center: No. 403, Building 3, Xinhui City Jingyuan, South Side of Dawan Metro Station,

Tel: Mr. Wang 18306136363

Yaruida (Hefei) Decorative Building Materials Co., Ltd. (Branch)

Address: In the courtyard of Sibao Cable Factory, Wenzhong Road, Yaohai District, Hefei City, Anhui Province

Tel: Mr. Zhang 15156980083

Astec (Shijiazhuang) Decorative Building Materials Co., Ltd. (Branch)

Address: No. 4-114, No. 289, Heping East Road, Chang'an District, Shijiazhuang City, Hebei Province

Tel: 0311-85521592 Mr. Wang 13903312353